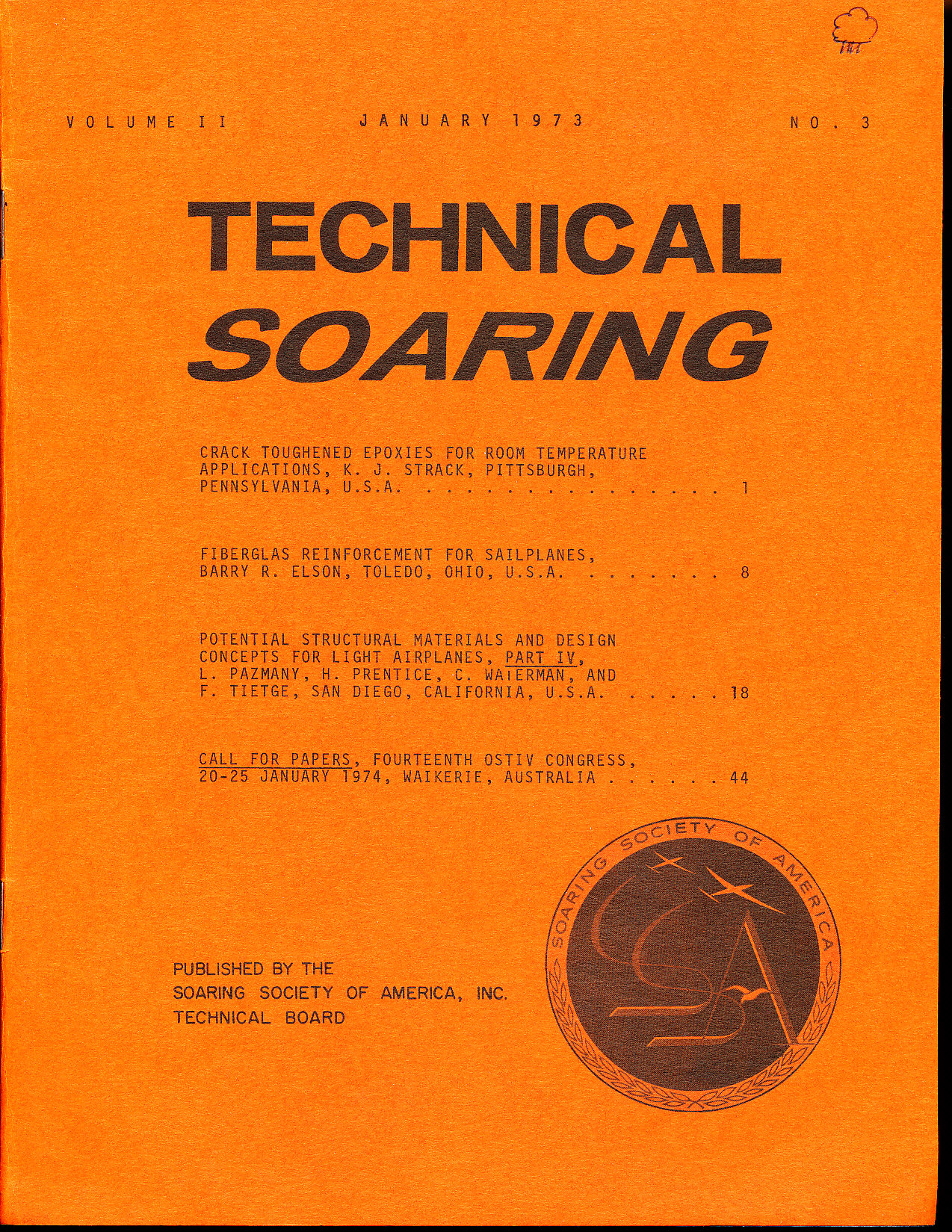

CRACK-TOUGHENED EPOXIES FOR ROOM TEMPERATURE APPLICATIONS

Keywords:

Structures, Materials, DesignAbstract

Ordinary epoxy resins used for laminating glass fiber reinforced plastics are glassy polyrners and are known to be brittle. A manifestation of this brittleness is the ease with which rnicrocracking of laminates made with such resins takes place, even at low levels of loading. Recent work has shown that it is possible to toughen epoxies by reacting them with small concentrations of a liquid carboxyl terminated butadiene acrylonitrile copolymer. If the proper microstructure of the resulting polymer is achieved, its surface fracture energy is typically an order of magnitude higher than that of the unmodified systern. When such toughened epoxies are used for laminating, microcracking, which ordinarily can be extensive, is reduced or even eliminated under conditions of cyclic fatigue loading. Application of toughened systems published to date has been difficult in the case of large lay-ups because of specified needs. These are described herein in which a simple prereaction technique is used to make possible toughened resins which then can be cured at room temperature.Downloads

Issue

Section

Articles

License

CLEARANCE AND LICENSE TO PUBLISH:

This paper is UNCLASSIFIED (for public reasons) and has been cleared by the appropriate agencies, company and government. This paper represents original work by the author(s). No portion of the material is covered by a prior copyright; or for any portion copyrighted, the author has obtained permission for its use.

I hereby license OSTIV to publish this paper and to use it for all of OSTIV's current and future publications uses.